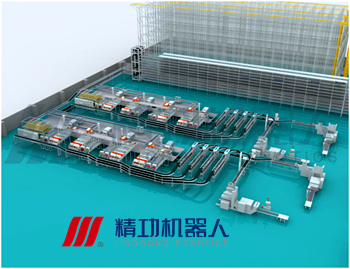

Automatic warehousing logistics system from gathered to flow science and technology innovation make wise move line for product.

JINGGONG ROBOTICS is a professional automatic logistics system integrates and automatic logistics equipment suppliers. Its intelligent logistics equipment including: automated mufti-layered storehouse system, stacker, AGV, pelletize(demolition) robot, RGV, conveyor system, high speed sorting system, electric control system and computer software system, etc. Applications include automated stereoscopic warehouse, warehousing logistics center and distribution center, various AGV transportation, testing lines, car assembly line.

1. Automatic logistic equipment

1.1 System integration

1.2 System simulation

1.3 Electrical control system

1.4 Computer system

2. Automatic logistics system integrates

2.1 Stereoscopic warehouse

2.2 Flexible conveyor system

2.3 Stacker

2.4 logistic distribution management system

1.Automatic logistic equipment

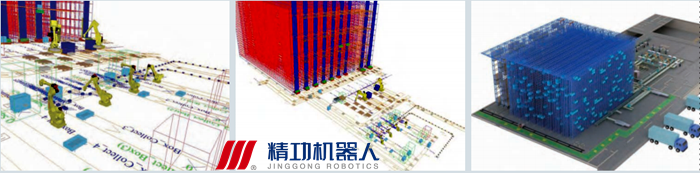

1.1 System integration

Jinggong robot can provide the automated solution and equipment for production, tooling, storage and transportation, can provide complete solution for digital operation workshop, connect with enterprise ERP or EMS system. The system combine planning and project implement, information technology and modem management technology, Automation proprietary technology and Strong system integration capability combined with industry characteristics.

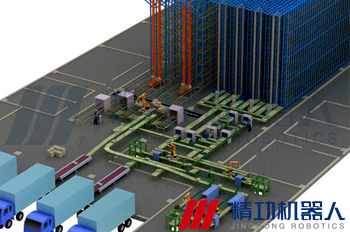

1.2 System simulation

To apply the Simulation technology and calculation method into logistics field, can forecast future logistics system at the stage of designing, and make the entire efficiency assessment. It give the quantitative performance indicators to key unit of equipment and subsystem, and find the bottleneck of system by simulating at the stage of project execution, then give the effective solution, it provide the key decision basis for varies of customers in different field.

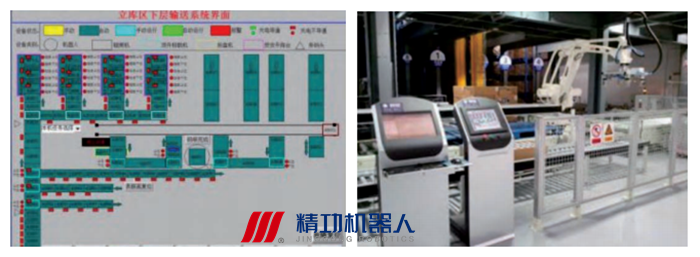

1.3 Electrical control system

Electrical control system is key part for the whole Automatic three-dimensional warehouse system equipment, it is connected with dispatching computer at the upriver and receive the command of material handling, connected with transportation equipment at the downriver to realize the driven,detective, reorganization of those equipment, accomplish the material transportation and transfer the information during the processing. The system adopt: “distributed control and centralized management”

1.4 Computer system

Jinggong robot has developed Basic business platform and development platform of computer logistics software system with own proprietary intellectual property rights,it include: Basic parameter configuration, task management, monitoring and dispatching, statistical query, data collection, Wireless terminal and intelligent interface system, etc.

2.Automatic logistics system integrates

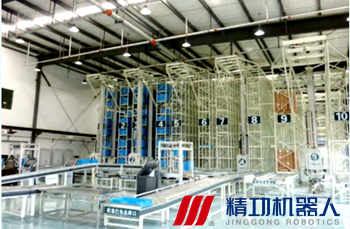

2.1 Stereoscopic warehouse

Our Stereoscopic warehouse solutions carry many advantages such as realizing for the warehouses comprehensive information automation, fine management, guiding and regulate warehouse personnel in their daily routine, improving the warehouse management, integrating warehouse resources, and therefore bring great value to the users.

2.2 Flexible conveyor system

Flexible conveyor system is mainly means the automatic guided vehicle- AGV which move inside of the workshop or warehouse, rail shuttles, and the transportation lines. AGV adopt laser, magnetism or inertial navigation mode, move according to programmed route, meanwhile, it realize the function such as transfer, lift, assemble, clamping, and fork take, it make the flexible operating for production and logistics delivery.

2.3 Stacker

Jinggong robot is a company who can independent develop and manufacture laned type of stacker and lifting equipment and its controlling system. The company possess integration capability of designing , manufacturing, assembling and service, can provide customer all kinds of stacking production and technical service, also can provide customized solution based on more advanced technology.

2.4 logistic distribution management system

Logistics and distribution system provide complete information management solutions. It features like: The system operation is simple and intuitive, support multi languages, Parameterized configuration, Dynamic plug-in extension. It provide the dispatching center the optimized selection and allocation strategy, improve the working efficiency.

By managing the lifecycle of the project, the system can ensure its stability and high reliability index, satisfy the system to run continuously for a long time. Currently, this system consist of TARS of distribution management (AUTOMATIC REPLENISHMENT), TASS(Auto-Sorting System) and TINF module for Auto-Sorting System

1.Chemical fiber industry

2.Beverage industry