MANUFACTURING EXECUTION SYSTEM

MAKE A DECISION WHEREVER YOU ARE, RUN THE COMPANY PERFECTLY JUST BY MOVING

YOUR FINGERS EIGHT MODULES BUILDING ENGINES FOR ENTERPRISE INFORMATIZATION

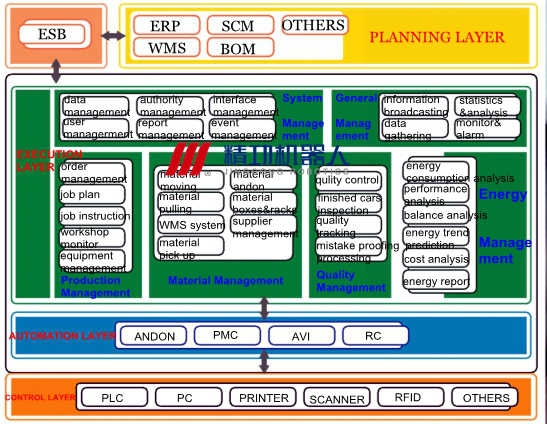

We deeply know the importance of execution layer to the enterprise Information. The industry needs a reliable executive system to make the Information management simply, improve efficiency and makes a convenient environment. This is why we persist in creating "JG- MES" system. JG-MES manufacturing execution system includes two levels of application, which is executive layer and automation layer. It builds eight management modules innovatively, become a bridge to connect the planning layer ERP and the bottom control. Every modules are independent and still integrated, it can be carried out in stages to promote MES, makes the information process more convenient and easy, to meet the manufacturing enterprises "unified

planning, step by step implementation" needs.

The jg-mes platform consists of two levels of application, the executive layer and the automation layer. The executive layer includes four business modules: production management, material management, quality management and energy management. Automation layer including ANDON, AVI, PMC and RC four big business module, implementation process the main core business covers production, mutual integration between various modules, can be used alone, also can the whole application, satisfy the current auto enterprise of "unified planning, step-by-step implementation of" informatization planning principles, can be divided into stages, divided into modules of MES implementation progress.

JG-MES is located in the middle execution layer of enterprise informatization planning, which is connected with planning management information of the planning layer, which is decomposed into executable tasks and completed information feedback planning layer. Next, the control layer is connected to monitor the operation of the underlying automation equipment, transfer the operation instruction requirements, and finally form the information closed loop. Provide external interface with ERP, DMS, SCM, BOM software system, PDA, RFID, PLC and other hardware platforms to realize timely data transmission and information integration.

JG - MES platform has strong integration capabilities, able to with enterprise ERP/PLM/CAPP, and other information system integration, such as SAP, UGS and PTC, for enterprises to build from production field to upper management of the comprehensive information solutions. Meanwhile, Jinggong robot MES can be integrated with ERP/PDM/CAPP system of other brands in China.

MES manufacturing execution system- function structure

1.Integration of IT technology and automation technology

Integration MES solution, pioneered the industry automation and information of perfect fusion, up to undertake ERP management system, undertake down bottom of PLC control system, fully support manufacturing production process control. Through system integration, EAI and ESB interface and software using the OPC technology, integrated automation equipment, dynamic data, graphical display equipment state information, remote monitoring of field equipment running state.

2.Follow advanced technical standards

Follow the idea of SOA service as an abstract method, the system in the enterprise application of different functional units abstract for the service, through well-defined interfaces and contracts between these services. According to isa-95 international standard and based on JG-MES platform, application plug-ins for different industries have been developed to form MES solutions for various industries.

3.Provide MES self-development technology platform

Technology independence refers to the "shield" the operating system, software infrastructure and other technical details, developers in the use of business infrastructure platform development and management software application system, focus on business logic, business enterprise management mode, and don't care about what specific technology to realize. This technology independence, but also realized the independence of the cross-platform operation, through the development of configuration software can run successfully in a variety of different heterogeneous environment, at the same time for the secondary development provides the convenience and feasibility.

4.Production process data acquisition technology

Using powerful data collection engine, integrate data acquisition channels (RFID and bar code equipment, PLC, Sensor, IPC, PC, etc.) to cover the entire factory site, ensure that large amounts of field data in real time, accurate and comprehensive collection. According to the production process of different production workshop information collection objects, the frequency of different requirements, using hierarchical/workshop information collection technology, better realize the collection of the workshop production information. For the production information with fixed objects and low frequency of information collection, a more extensive manual real-time input production information collection method is adopted. For the production information with a large number of acquisition objects and a high frequency of information collection, the information collection method of "barcode + handheld PDA" or "barcode +PC+ barcode scanning gun" is adopted. In the case of bad environment (such as coating workshop of automobile factory) or high requirement of data automatic collection, RFID method can be adopted to fully automatic collection without manual operation and high efficiency.

5.Multiple factory data models are supported

The factory data model is the core of the whole MES application system and the basis of all relevant application system integration and data exchange within the factory. From the core business processes of the production process management and control, analysis of the relevant business processes and process data, accurate description key auxiliary factory key value-added business data and business data, and with reference to the ISA - 95 standards, established a MES factory suited to the characteristics of the discrete manufacturing enterprise production process data model, including business model, function model and information model. Support multiple factory organization structure, can be achieved between many factory under the group extended application, using a set of software platform, a set of basic data, and manufacturing business synergy between multiple factories, can reduce repeated investment.

6.Perfect functional modules

MES the implementation of the platform after years of accumulation of experience, formed a functional solution, covering the production management, quality management, material management, equipment management, Andon management, data acquisition, automatic control, such as module, to help manufacturers improve production management level, to implement lean manufacturing, improve product quality, reduce production costs.

JG-MES manufacturing execution system is widely used in automobile, automobile parts, machinery, food, pharmaceutical, energy and other industries.

Automobile whole car, automobile parts, machinery industry, is a typical discrete manufacturing industry, both by order production, also by inventory production; There are both batch production, but also single small batch production. And complicated manufacturing process, factors affecting the complicated and changeable production status, thus easy to produce the result: the manufacturing process for companies in the opaque state, that the manufacturing enterprise manufacturing process control is very poor. As a very key basic information system in enterprise informatization, MES can play a very important role in the control and improvement of the production and manufacturing process of enterprises. Through the MES system, can effectively in the process of the enterprise manufacturing all kinds of manufacturing process information real-time management, make the information transparent state, in the enterprise and can be accessed at any time, which can real-time understanding of the enterprise real production status. At the same time, through the analysis of real-time production information, find out the various factors influencing the enterprise production process, the gradual improvement of these factors in stages, to improve and optimize the enterprise production process, fundamentally solve the problem of discrete manufacturing industry production process control.

Food, pharmaceutical and energy industries are typical process manufacturing industries, mainly by inventory, batch, continuous production methods. Process manufacturing industries, in the process of production process, can produce various of products, by-products and waste, return, etc., the management of the materials need to have strict batch number.

Case 1

In the auto industry, for example, to implement the lean production of the car, on the shop floor level one of the most core problem is how to process the vehicle synthetical use of all kinds of information flow, the information processing by information system for further refining, which extends to the automatic equipment factory, quality management, delivery management, supply chain procurement, cost control, logistics management, and other external links. In simple terms, is the vehicle in the workshop production form unlimited amplifier and sharing, as used by various external link, through such way to achieve the efficiency of management and resource allocation optimization. On the basis of summarizing the implementation of MES system in automobile industry for many years, jinggong robot has formed a complete MES solution.

Case 2

Food, pharmaceutical and energy industries are typical process manufacturing industries, mainly by inventory, batch, continuous production methods. Process manufacturing industries, in the process of production process, can produce various of products, by-products and waste, return, etc., the management of the materials need to have strict batch number. For example, the drug production process in the pharmaceutical industry requires very strict batch number records and tracking, from raw materials, suppliers, intermediates and products sold to users. Batch management and traceability are the management focus of the pharmaceutical industry. Once the batch quality problem is found, the related drugs can be recovered from circulation as soon as possible. The MES food solution of jinggong robot realizes functions such as central kitchen, cold chain logistics and store management, and fully meets the whole process management needs of food enterprises from production life cycle and sales.

JG - MES manufacturing execution management system can provide users with a quick response, elastic, intensification of manufacturing environment, and help enterprises to reduce costs, timely delivery, improve the quality of the products and improve service quality. Standardize various information processing processes within the enterprise, improve the proportion of the completion of the enterprise according to the contract period, and increase the transparency of various information in the enterprise.